Development Overview of PVC Pipe

PVC pipe was first developed and produced by a German company in 1936, and the product has received widespread attention.

By the 1950s, developed countries such as Europe, the United States, and Japan were accelerating the development of PVC pipes. The development of product production and application technology is very rapid, and there are ordinary straight pipes, single-wall corrugated pipes, double-wall corrugated pipes, etc. in the product structure.

In addition to polyvinyl chloride, there are polyethylene, polypropylene, polystyrene, ABS, reinforced polyester, etc., but the mainstream products are still PVC pipes, accounting for more than 70% of the total plastic pipes.

PVC pipes are mainly used for building water supply and drainage, municipal water supply and drainage, agricultural irrigation, and industrial pipes with special requirements.

At present, more than 90% of the newly built water supply pipelines in some developed countries use PVC pipes. The use of PVC pipes for municipal drainage is also very common, and the proportion of use is increasing year by year.

The pipe diameter of building water supply and drainage pipes is small, mostly D100~200mm. The pipe diameter of municipal drainage pipes is generally larger. PVC pipes are mostly used below D450mm. Although there are products with diameters of D500~D900mm and above, due to the higher cost, they are used less.

The United States has been using PVC pipes for more than ten years and is one of the largest producers of PVC pipes. It is mainly used for building water supply and drainage and municipal water supply and drainage. The products used for municipal drainage are mostly single-wall corrugated pipes and double-wall corrugated pipes, and the technical standard for double-wall corrugated pipes has been formulated: ASTMF949-890.

Germany is the earliest country to develop and apply PVC pipes. In 1989, the consumption of plastic pipes in the western region alone reached 393,000 tons, and 50% of drinking water pipes used PVC pipes.

The double-wall corrugated pipe production technology developed in the 1970s represents the advanced level and development direction of today’s plastic pipes.

Due to the annular hollow section, the double-wall corrugated pipe can have a high compressive strength, which can save 50% of raw materials compared with ordinary plastic pipes of the same specification, while the strength and other properties remain unchanged.

It is not only light in weight, and high in strength, but also low in cost, easy to connect pipes, and has high production efficiency. It has more advantages than other pipes, so it is widely used in water supply, drainage and agricultural irrigation, and other projects.

The development of plastic pipes in Japan was relatively late, starting in 1951, but it has developed rapidly, and the application field has rapidly expanded from building drainage to urban water supply, drainage, agricultural irrigation, electric power telecommunications, and some pipes for industrial transportation of gases and liquids.

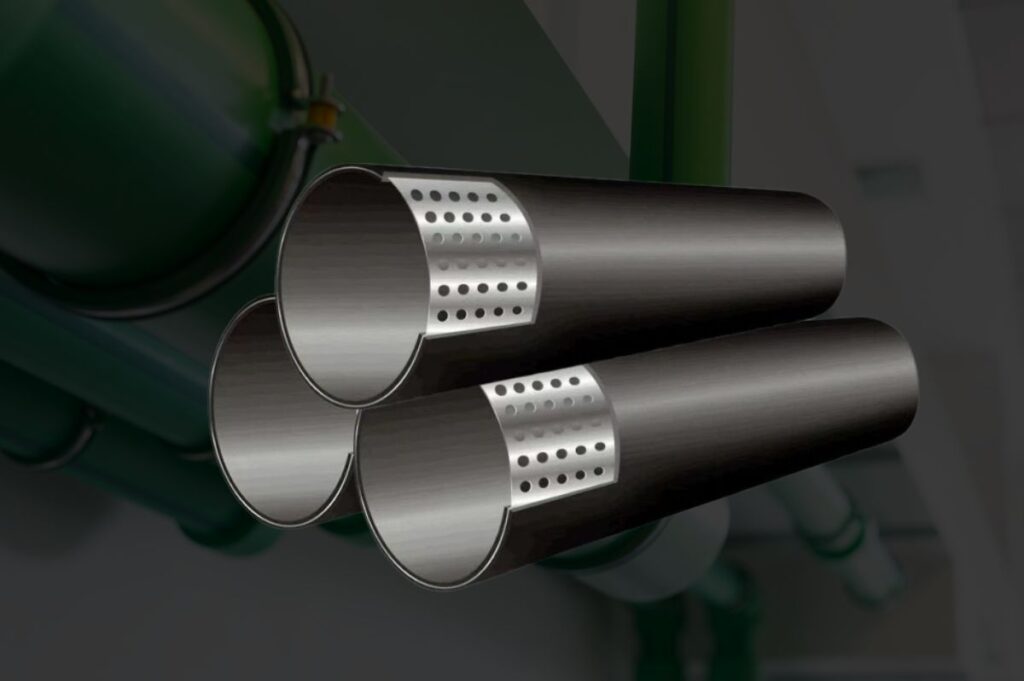

In 1990, the product of PVC pipes was 520,000 tons, and pipe fittings were 57,700 tons, and the annual growth rate was 3.2%. In addition to ordinary plastic pipes of the equal section, the pipes used for municipal drainage have also developed high-rigidity pipes with small holes in the pipe wall.

The section forms are round and oval, and the maximum diameter can reach D1200mm. It is characterized by high rigidity and high strength and can withstand large external pressure loads.

By the end of the 1980s, Japan has successively developed single-wall corrugated pipes and ribbed coiled pipes. From 1953 to the 1970s, unified technical standards have been formulated for the production and application of plastic pipes.

The proportion of PVC pipes in engineering applications is developing very fast. According to Japanese statistics, the proportion of PVC pipes in sewer construction was 47% in 1988, 53.5% in 1990, and 59% in 1992.

In 1992, the total length of sewer construction in Japan was 12,942.8km, and the pipeline below D450mm was 11,567.9km, accounting for 89.4% of the total length.

PVC pipes are used in 7619.5km of pipes below D450mm, accounting for 66% of the total length of these pipes, while the proportion of PVC pipes used in pipes below D200mm has reached 82%.

It can be seen that PVC pipes have become mainstream in drainage pipes below D450mm and are rapidly replacing concrete pipes.

Pipes above D500mm are still dominated by reinforced concrete pipes. D500mm or more, medium and large-diameter PVC pipes are also used, but only 1.9% are used.

In general, the application of PVC pipes in drainage projects is becoming more and more common, especially in pipes below D450mm, PVC pipes have become the mainstream, the product structure is constantly being updated, and the pipe diameters also tend to develop in a larger direction.

The development of PVC pipes in China started late. It was first used in the indoor drainage of the construction industry in 1978 and later expanded to the water supply field.

The 1980s entered a period of development. From product production to engineering applications, there has been a large increase.

In 1986, the national standard (GB5836-86) for rigid PVC pipes and fittings for building drainage was formulated.

In 1989, the Ministry of Construction promulgated the CJJ29-89 and the CJJ30-89. Corresponding standards have also been formulated in terms of water supply.

After decades of development, China has also made breakthroughs in the manufacture of PVC pipes.

China not only widely uses PVC pipes in the country. Relying on its strong manufacturing capacity, China’s PVC pipes are also exported abroad in large quantities.

From a global perspective, the production technology of PVC pipes has matured.

▲ NBQXHY PVC Pipe Factory

NBQXHY is a professional manufacturer of PVC pipes and pipe fittings. If you want to know more details about pipes, please click here.

Alternatively, you can contact our experts directly.